DIY Watch dial feet soldering machine, last update 17.04.2020

Tools > Contemporary

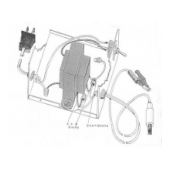

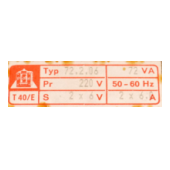

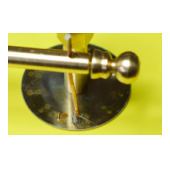

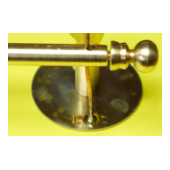

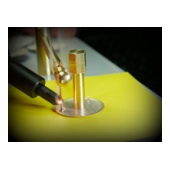

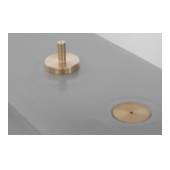

It all started with a PDF file with chapter XX "Dial Positioning For Retrofits" of the book "Quartz Watch Retrofitting Manual" from Wesley R. Poor. After checking other sites and resources I wanted to make one myself as the price for a ready-made one is 300 $ plus depending on the brand.Project: Dial Feet Soldering Machine on a budget.Items bought add up to 35 € and the rest are out of the odds and ends box.I use an AC transformer, open design, 2 x 6 V as this was available in the local electronic shop. I use only 1 x 6 V as written in the PDF file and shown on the drawing.The carbon rod is from a zinc-carbon battery glued into a little plastic tube and then drilled so that a standard 4 mm banana plug cable assembly can be used.The parts to hold down the dial and the feet positioning arm are made from brass stock I had lying around. The size of the parts is just according to the stock material.For soldering, I use copper wire, "Löthonig" as flux and lead-free 99.3Sn0.7CU solder.To straighten the copper wire fix one side in a vise and hold the other end with a pair of pliers. Give the pair of pliers a good sidewards tap with a hammer. Then cut off the straight part you need.This machine is not for sale and I will not build more. If you intend to solder feet to dials you are able to build a machine like this one yourself.

Cleaning the spot for soldering is essential and the the solder paste needs to be properly around the copper wire to give a good joint.