Reverse engineering a Junghans J9, updated 18.01.2020

Workshop > Projects

On this site, I will display the process of reverse-engineering the Junghans J9 movement.

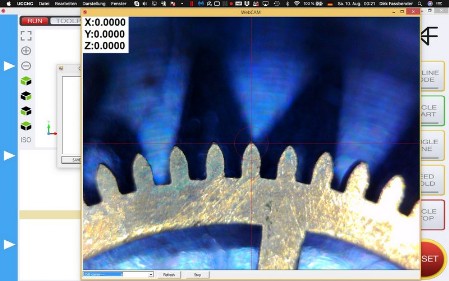

This is my Stepcraft D300 fitted with an Andonstar USB microscope for precise measuring of the watch parts.

I can use my Sherline collet equipment on the Stepcraft to hold the watch parts.

Just a reminder of how small the parts are.

The Andonstar microscope makes it possible to measure distances up to one-hundredths of a millimeter.

The biggest challenge so far is the workflow in Fusion360. There are a lot of coordinates and measurements to deal with and on the main plate, I put every point on one sketch. This needs to be changed as I lost the overview. It is almost not possible to find specific points again if they need adjustments.

With the use of the CNC machine, I get XY coordinates as precise as to the specifications of the machine. Using these coordinates as such within Fusion360 is possible, but it gets very confusing as it is all related to a zero point. A better way, in my opinion, is to use the old method using circles to construct the points. Therefore I convert the XY coordinates into distances which can be easily used to construct the intersections for a needed center point. I made an excel spreadsheet to calculate the distances.

As the minute wheel and the second wheel have defined position it is always possible to construct the other center points with three circles. Another advantage of this method is that I do not need to align the movement plate on the CNC machine with a reference. I just put the plate in the movement holder and start centering the crosshair over the relevant point, hit ESC, which copies the current coordinate into the memory, and move to the next point, hit ESC and so forth. When finished I save the coordinate file for further use.

A first test of the Fusion360 animation feature.

I can recommend this book as it covers in extenze the building of a pocket watch with a lot of explanations. "Die Lehre an der Deutschen Uhrmacherschule" a book from Schreck/Hess/Helwig. The book is from 1925 and you could build the pocket watch today as all numbers are in the book as well as the details of the making.

23.08.2019 - Details, error management. Now that all parts are constructed the correct placement is necessary. Using joints is the best way to do this but there are some challenges that I have not overcome yet. The balance spring will be attached to two parts and for the time being. I have no clue how to do it. While I'm dealing with the issue, it happens that I unintentionally alter or even delete some other joint, which I did not recognize immediately and gave me that "What happened here" feelings. Time for a break!

With a little planning, the construction became much more overseeable. Essential is the proper renaming of joints, sketches, and components.

Below the current project, status rendering from Fusion360